Appropriate communication and organization for your maintenance tasks

In order to ensure an appropriate organization of your maintenance activities, you need a suitable tool allowing you to easily communicate with your colleagues. Production employees should be able to quickly and efficiently inform you of any problem they encounter. For their work preparation, work planners should set to work with any available information about a machine or an installation. The executors of a maintenance task have to know exactly which tasks have been assigned to them and which specifications they need to follow for the execution of the task. In the end, the maintenance manager is interested in the statistics of the maintenance service and its performance.

With the work order management functions of Rimses, all parties involved are able to communicate with each other and exchange information smoothly, which increases the efficiency.

Requests

Rimses offers various capabilities to record a failure or any other issue.

With the requests functionality in Rimses or in eRimses (web requests), a production employee is able to directly inform the maintenance department about all tasks to be executed.

This allows all tasks to be registered in the system and prevents any information loss. It even prevents the maintenance employees from being continuously disturbed by phone calls. The requestors themselves can follow the status of their failure or issue.

Logbook

Is your company obliged to log every action that occurred during a shift? Rimses allows you to keep a logbook. This electronic logbook allows employees not only to register communicative messages, but also register notifications for work requests. It provides feedback about the registered work orders as well. The logbook can be printed in its entirety or for a specific period, depending on the filters you have defined.

Work preparation

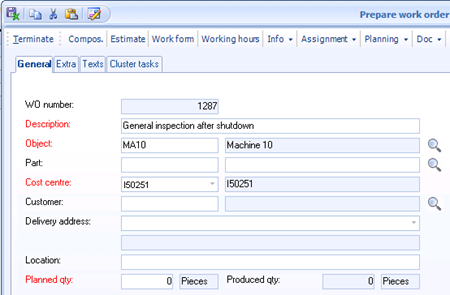

In order to organize the maintenance department properly, the work planner can use various tools to prepare and plan all activities.

The work order overview has very extended and flexible selection criteria which allow the work planner to group the work orders by status, department, priority, installation, work type, etc...

As such, the work planner can prepare certain tasks in a targeted way, based on an estimation of the activities to be executed, including the required material, orders and tools. The work planner can enter work instructions or he can base the work on standard tasks.

He can take safety into account by using working papers, LOTO-procedures (Lockout Tagout), required documents, authorizations, acceptances and required post inspections.

Planning

For the work order planning, the work planner can use the extended planning tables in Rimses.

To-Do list

The technician can easily see the work that has to be done.

He can consult all information on the work form or print the work form including all linked documents. When terminating the work, the technician can enter a description of the work he executed and record the worked hours, the materials that were used, and the various costs as well. By registering the used materials, the stock of spare parts is also brought up to date. If needed, a technician can immediately create a follow-up order.

Statistics and information

Once a work order has been terminated, you can use the powerful selections of the work order history to sort work orders on the basis of installations, incurred costs, work types, symptoms, causes, actions, failure categories, ...

Rimses Analyzer allows you to perform extended analyses on the

information contained in the work orders. As such, you can see how your KPI's (Key Performance Indicators) are evolving.

Functions proposed:

- Requests

- Logbook

- Work preparation

- To-do list

- Standard reports

These functions are available in the products:

The Planning function is available in following products: